If you have been reading our blog posts on

Expanded PTFE, then you know that it is PTFE’s trade name. This material has

different applications that we shall look at in this article. But before we

dive into the in-depth analysis of the product, it is crucial to understand the

basics. Let us dwell our discussion much into what Expanded PTFE sheet is including how it is made.

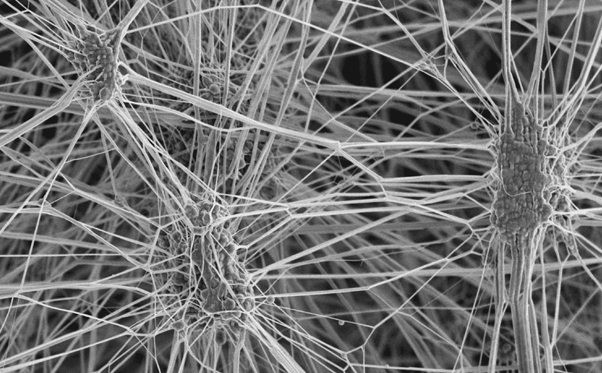

Teflex Gasket Co., Ltd is a renowned company that deals with the production of PTFE. Teflon is an important chemical used to manufacture different products. That is why many industry professionals have invested heavily in its acquisition. Those who are into studying chemistry understand that it is easy to visualize the molecular structure of this compound by analyzing its name.

But for those of us, who have not studied

the subject extensively, this compound is hydrophobic-it cannot stick to water or, better

yet, any form of water containing element. This means that it is

water-resistant. Teflon is also known for having low friction against solid

materials. That is why it is used to make non-stick cookware.

How

Teflon Is Made

PTFE was discovered by a youthful

scientist known as Roy Plunkett. It was totally accidental when he was

attempting to create a compound used for refrigeration. Initially, he hoped

that it would be possible to create that element by reacting some acid with TFE. In this

case, TFE is an element harvested from Teflon. To achieve excellent results, he

decided to store TFE gas in different cans.

Of course, he stored the same portion in

every can. After a few months, he discovered that while the weight of gas

contained in the cans did not indicate that the cans were empty, there was no

gas in the containers. So he eventually decided to saw the metal can apart.

The result of his action was a white

powder located on the pressure bottle. He called it Teflon. Over the years,

this compound has become famous as a significant compound used in the

production of various materials in different industries. Iron is its primary

catalyst.

Now

let us look at how PTFE coatings are usually made.

PTFE

is made using four major ingredients. They include chloroform, fluorspar,

water, in addition to hydrofluoric. Note, to form a unique coating, these

compounds will be combined to form a chemical reaction in a chamber. Usually,

it occurs when all the elements are heated between the temperatures of

1000-1600 degrees Celsius.

The PTFE has to be synthesized from

chloroform and fluorspar. The ingredients need to be combined through pyrolysis, which is a

prominent chemical process. Typically, PTFE is flammable. This implies that

moving it from one point to another can be risky. For that reason, the phase

has to be conducted on-site. This is where PTFE is usually created.

Teflon

Sheets- What Are They?

As their name suggests, Teflon sheets are just

sheets made of the Teflon material. Usually, they are produced when methane is

reacted with hydrogen chloride. Chlorine is then added into the solution.

Conclusion

Teflon (PTFE) has a variety of uses that

you need to weigh on. This is true if you are a professional looking forward to

investing in a particular industry within the scope of manufacturing products.