In various industries, the need for specialized components with unique shapes and superior performance is ever-present. Custom forging, a widely utilized manufacturing technique, provides the perfect solution for meeting these specific requirements. In this article, we will explore why custom forging is considered the optimal choice when it comes to producing parts and products that meet special demands. From its versatility to the advantages it offers, custom forging proves to be a reliable and efficient manufacturing process. Welcome to visit the forging parts manufacturer – cxinforging to learn more!

Versatility of Custom Forging:

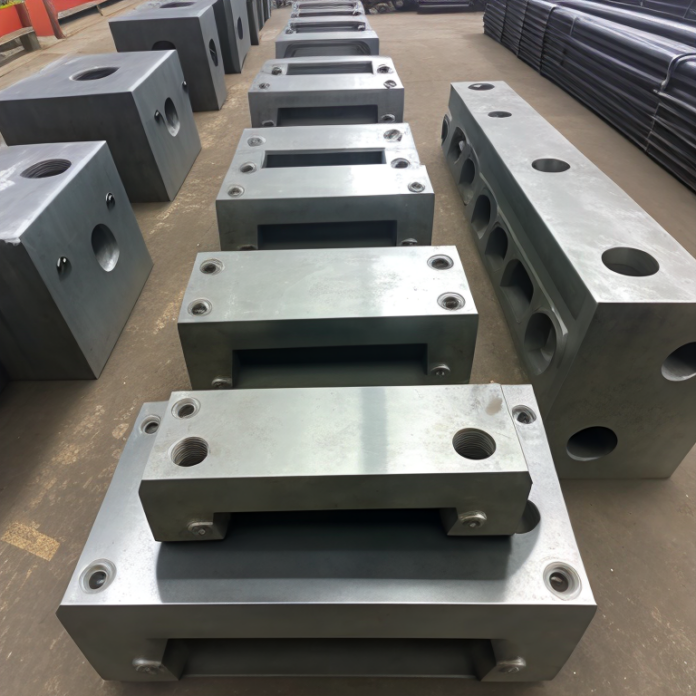

One of the primary reasons why custom forging stands out as the preferred choice for meeting special requirements is its versatility. The process of custom forging involves shaping and forming metal through controlled heating and mechanical pressure. This versatility allows manufacturers to produce components with intricate designs, complex geometries, and precise specifications. Whether it’s a unique shape, a specific material requirement, or a need for enhanced mechanical properties, custom forging offers the flexibility to create parts that perfectly align with the desired specifications.

Meeting Special Material Demands:

Certain industries require components that can withstand extreme conditions or possess specific material properties. Custom forging excels in meeting these special material demands. With custom forging, manufacturers have the ability to choose from a wide range of materials, including carbon steel, stainless steel, aluminum, titanium, and more. By carefully selecting the appropriate material for a specific application, custom forged components can exhibit exceptional strength, durability, corrosion resistance, heat resistance, or any other desired material characteristic.

Enhanced Mechanical Properties:

In addition to meeting material demands, custom forging offers the advantage of enhancing the mechanical properties of the forged components. The process of forging, through controlled deformation and grain flow, aligns the internal structure of the metal, resulting in improved mechanical properties such as increased strength, toughness, and fatigue resistance. This makes custom forged components ideal for applications that require high reliability and performance under demanding conditions.

Cost-Effective Solution:

Contrary to the misconception that custom forging is a costly process, it can actually be a cost-effective solution in the long run. While the initial tooling and setup costs may be higher compared to standard components, custom forging eliminates the need for extensive machining, welding, or assembly operations. The ability to produce near-net shape components reduces material waste and minimizes the amount of machining required, resulting in cost savings. Furthermore, the enhanced mechanical properties of custom forged components often lead to longer service life, reducing the need for frequent replacements and maintenance.

Collaborative Approach and Expertise:

Another advantage of choosing custom forging is the opportunity for a collaborative approach between manufacturers and customers. Custom forging manufacturers typically possess extensive expertise and experience in the field, allowing them to work closely with customers to understand their unique requirements and provide tailored solutions. This collaborative approach ensures that the final custom forged components meet or exceed the desired specifications, providing maximum satisfaction and value to the customers.

Conclusion:

When it comes to meeting special requirements in manufacturing, custom forging emerges as the optimal choice. Its versatility, ability to meet material demands, enhanced mechanical properties, cost-effectiveness, and collaborative approach make it a reliable and efficient solution. By opting for custom forging, industries can ensure the production of components that are perfectly suited to their specific needs, resulting in improved performance, durability, and overall satisfaction. Choose custom forging as your manufacturing process of choice and experience the benefits of meeting special requirements with precision and excellence.