Injection molding is one of the predominantly used manufacturing processes in the fabrication of different plastic materials. Usually, various products are manufactured using this process. They vary in size as well as the type and uses. In the long run, the idea is to utilize the process in the creation of a high-quality plastic commodity. For that reason, it’s essential to learn more about injection molding. Here are the top reasons for using plastic molding in the manufacture of plastic parts.

- Enhanced Automation Will Save Time

Of course, plastic molding automation is a viable process that’s also automated. The entire phase entails the incorporation of plastic into the creation of products. As such, most of the molding process will be conducted using a machine. Therefore, automation mostly helps in reducing various costs associated with manufacturing.

- Reduced Labor Costs

Since the process of plastic molding is automated, it’ll help the company in enhancing its productivity. As such, owners of the production process will be better placed to save on labor costs. That’s why most manufacturing firms are encouraged to incorporate this method of production.

- Increased Efficiency

Immediately the plastic has been created to meet the client’s specifications, the expert in charge of the entire project is tasked with the duty to oversee the whole project. There will be a high rate of production in this case. Therefore, the process will also take a short while. This will allow the creation of more parts from one mold.

- Injection Moulding Is Pretty Accurate

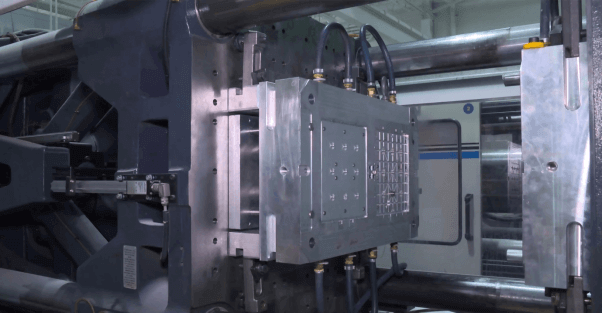

Plastic manufacturers with vast experience will agree with the fact that this is an actual process. Plastic injection molding is a viable precise process that can quickly fabricate different plastic parts. With that said, various design restrictions need to be observed by the manufacturers. The molds are used in creating the end-product.

- Enhanced Flexibility

When discussing flexibility, it’s vital to consider the process of plastic molding, including what it takes to be successful in the long run. Apart from being accurate, plastic molding is precise. The production process is also simple. This makes it flexible in different ways.

- You’ll Achieve A Smooth Product Finishing.

Plastic molding is an intense process. Therefore, it helps the manufacturer to acquire a smooth finishing. This is appended to the fact that the whole process is carried out professionally.

- The Process Is Resourceful

In the current era of production, consideration is given mainly to sustainability. This is because it’s commonplace for several manufacturing sectors. Developers have also settled for this same strategy. Therefore, it’s vital to consider implementing injection molding into your manufacturing process. It’s resourceful and economical.

Take-Home

Whether you’re a consumer or manufacturer, it’s vital to be familiar with the plastic molding process. By reading this article, you’ll garner vast knowledge on the same.