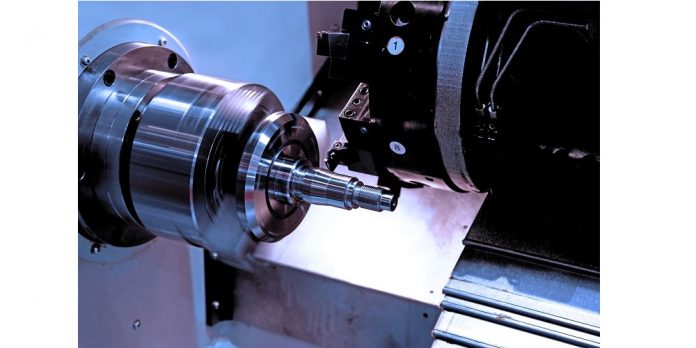

CNC machining is a leading manufacturing operation that includes a wide range of techniques or services. The most common CNC machining services are milling, turning, EDM, surface grinding, and WEDM. Each of these services is highly beneficial and applied in various industries. CNC machining involves the use of a wide range of materials like CNC aluminum. In this write-up, we discuss the various types of CNC materials used in CNC machining.

Materials used in CNC machining

In CNC machining, various types of materials can be applied. Below are some of the most common types of CNC materials;

1. Aluminum

Aluminum is the most widely used material in CNC machining. This is because of its significant aspect and mechanical components. Another reason for the widespread use of aluminum is the strength and resistance to wearing off. When aluminum is exposed to air, it forms a solid protective layer by reacting with oxygen. The layer is known as aluminum oxide. It protects the metal from corrosion and rust.

For this reason, the material is applied in a wide range of industries. It is used in automotive, aerospace, healthcare, good formability, and weldability industry. It is also worth mentioning that aluminum is easier to machine than other materials used in CNC machining.

2. Alloy steel

There are several types of Alloy steel on the market. Alloy steel is applied for making parts that need stronger welds and enhanced formability. This material requires strong welds, shafts, and gears. It can be used in high-stress applications. For instance, in the energy industry, alloy steel is used to make parts that require impeccable strength and corrosion-resistant properties. Steel CNC machined components are also used in the automotive and aerospace industry other than the energy industry.

3. Stainless steel

Another material commonly applied in CNC machining is stainless steel. It is an excellent material for making electronic components and medical devices. Stainless steel is highly weldable and formable. It is also a solid material because of its nonmagnetism and corrosion resistance. Stainless steel comes in varying grades, some of which are ideal for outdoor applications that require excellent strength. The material also features resistance to cracking, pitting, and corrosion.

4. Low carbon steel

This material is easy to machine hence its high application in the CNC machining industry. Low carbon steel is used for applications that need high strength. The material is also highly formable, weldable, and it features high machinability. The downside to this material is that it rusts easily when it is exposed to some environmental conditions. This is because of its magnetism.

5. Brass

Brass is highly applied for making materials that need strength and electrical conductivity. It is an incredible nonmagnetic material used with high visual appeal. It is recognized in the CNC machining industry as the easiest and most cost-effective material to use.

Conclusion

Apart from the incredible metals mentioned above, various plastics can also be applied in CNC machining. The most common plastics here are acetal, nylon, polypropylene, and PVC. These plastics are easy to machine and used in corrosion-resistant applications.